System film

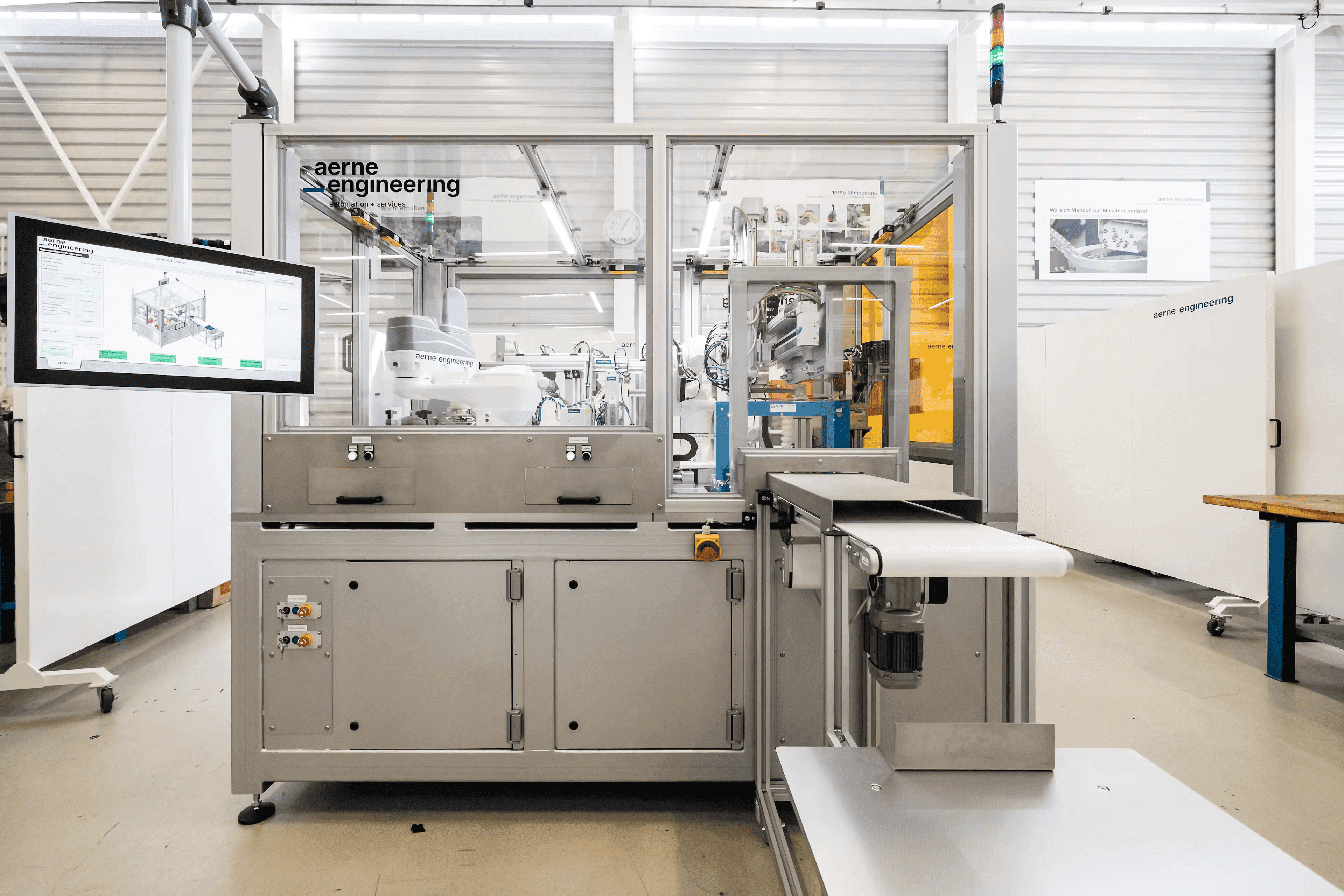

Assembly and packaging line for ventilation hoses

Robot

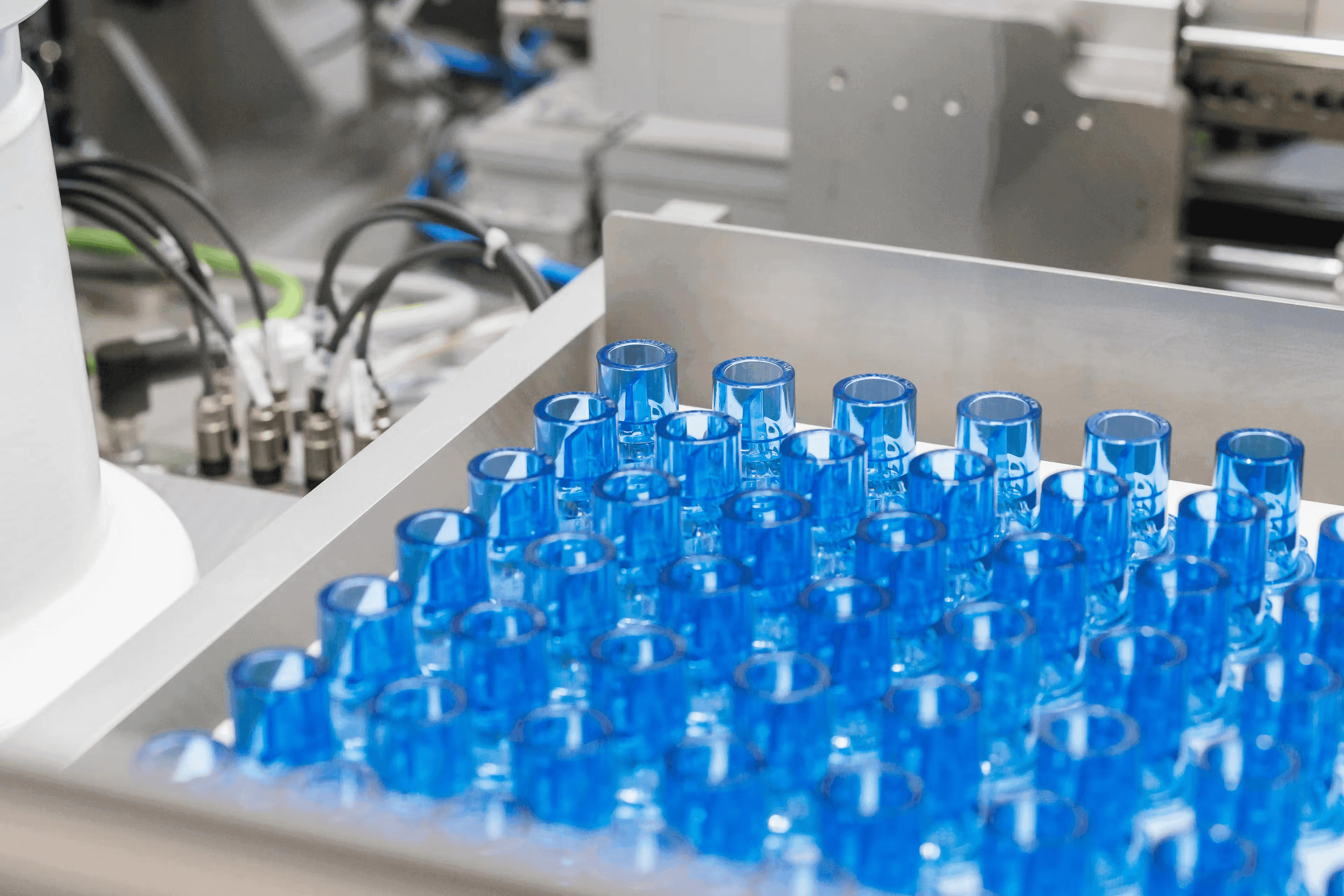

The operator can easily feed the bodys into the machine in the correct position via a double drawer system. With the drawer system, the customer has increased autonomy and can change a drawer during automatic operation, thus avoiding interruptions in production.

Adhesive station

A special UV adhesive is applied to the body. The tube is then pushed onto these points.

Joining station

At the joining station, the body is joined to the hose

Hose reel

The desired length of hose is prepared from a large hose reel. The operator can flexibly choose between five different hose lengths.

Changing station

The hose connected to the body is wound up into a screw.

UV light

At this station, the adhesive is cured at the joint using UV light.

Bandolier

The last process is to band the tube roll.

Benefits

Starting point

A compact automation cell is to be built for the automatic production of the ventilation hose. The system is to be flexibly convertible to different tube lengths.

Solution

With a compact automation cell with two robot systems, a customised system solution could be realised for the customer. In addition, a new roller clamping system, which allows clamping without a core, added value for the customer.

Advantages for the customer

- All lengths can be produced flexibly without change parts

- The hose reels can be clamped without a core

- The automation cell is very compact

- The intuitive HMI makes the system very user-friendly