Cutting machine

A success story in bakery robotics!

Coop, one of Switzerland's leading food distribution chains, was looking for an innovative solution to automate the cutting of bread automatically before baking.

With thousands of loaves of bread coming out of the ovens every day, the industrial bakery turned to us.

With the use of four industrial robots from Stäubli and ultrasonic knives from Swiss Sonic, a flexible cutting cell could be realised.

Simon Huwiler, project manager at Coop, and Marco Geiger, sales engineer at aerne engineering, tell you more about how this design makes it possible to meet the challenge of a perfectly crispy loaf of bread with an output of 17,000 cuts per hour, while at the same time relieving labour.

3-D Vision Sensor

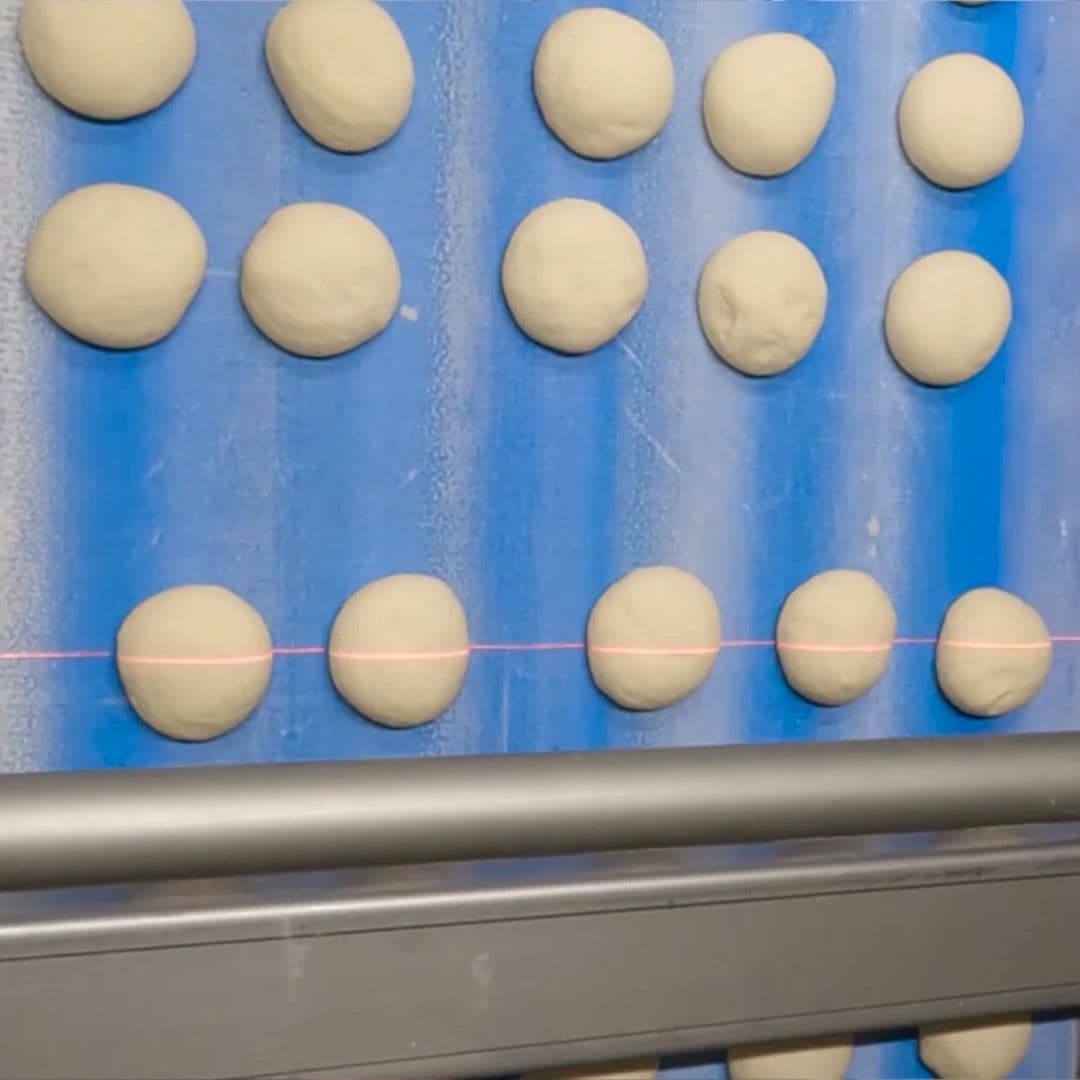

The dough pieces are conveyed under the 3-D vision sensor via a floured conveyor belt.

The coordinates in height, position and dimension determined by the sensor are forwarded to the robot stations.

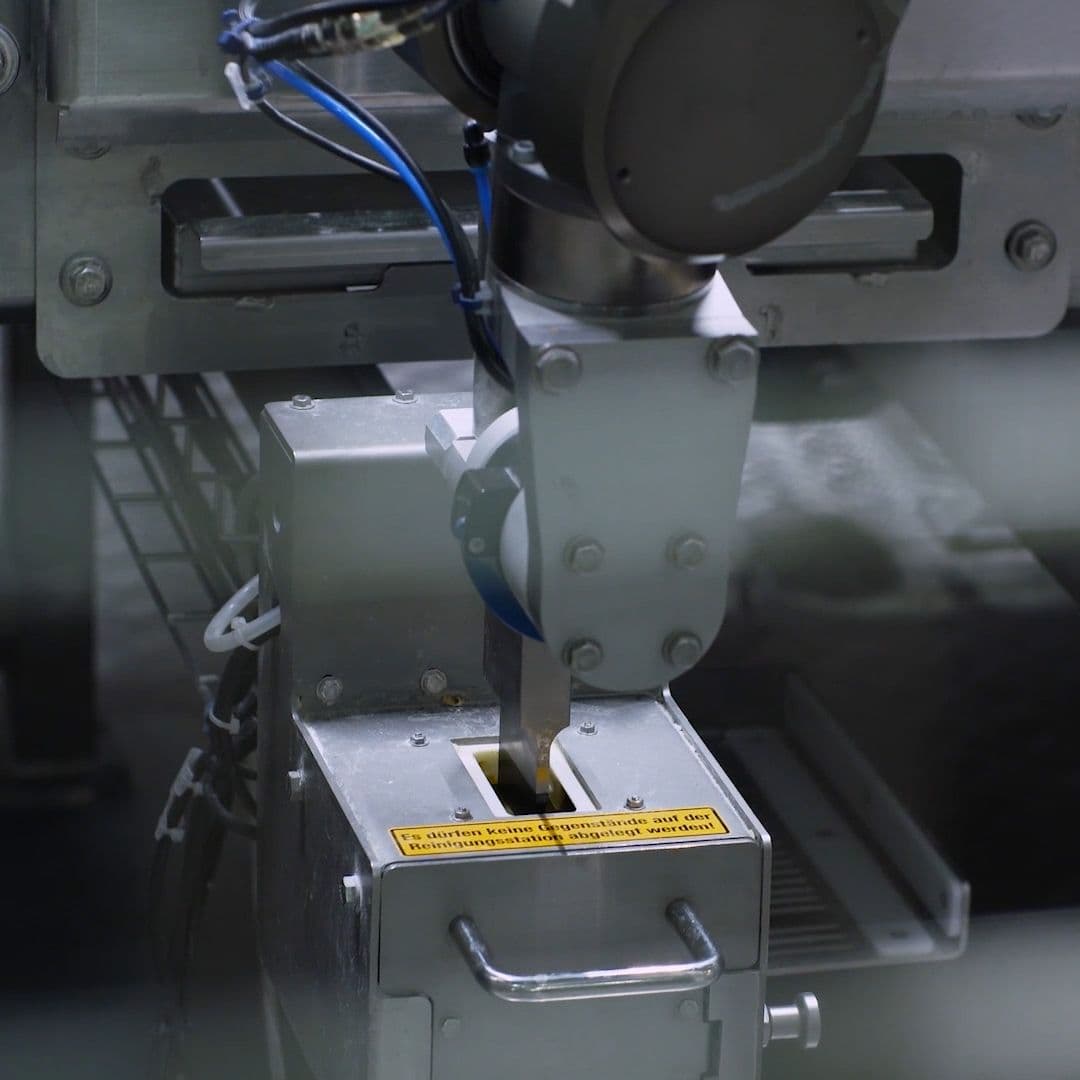

Ultrasonic knife

The ultrasonic knives with reduced cutting force guarantee that the dough pieces do not slip on the floured conveyor belt.

Automatic knife cleaning

An integrated automatic knife cleaning system prevents the blades from becoming gradually dirty.

Benefits

Initial situation

Cutting was a laborious and time-consuming process that had to be done by hand. The workplace was not ergonomically designed, which led to additional physical strain for the employees. Overall, the work was arduous and demanding for the staff.

Solution

The workplace was automated in a very confined space. By optimising and accelerating the processing, a lot of time could be saved. Thanks to the tracking mode, a perfect cut is made on the dough piece. The ultrasonic knives with their reduced cutting force guarantee that the dough pieces do not slip on the floured conveyor belt.

Advantages customer

- New products can be easily taught in by the staff on site.

- The component is modularly expandable and can be extended by further robot stations if required.

- Emergency operation function, so that in the event of a failure of the stations, they can be temporarily replaced by personnel.

- The system has a very small footprint and works in very confined spaces.

- Automatic blade cleaning prevents the blades from becoming gradually dirty.