System film

We present a packaging line for the food industry.

Toothed-belt shuttles

Baking trays are inserted into toothed belt shuttles

Separation system

The cakes meet the separation system

Side guide belt

The cakes are aligned on the side guide belt

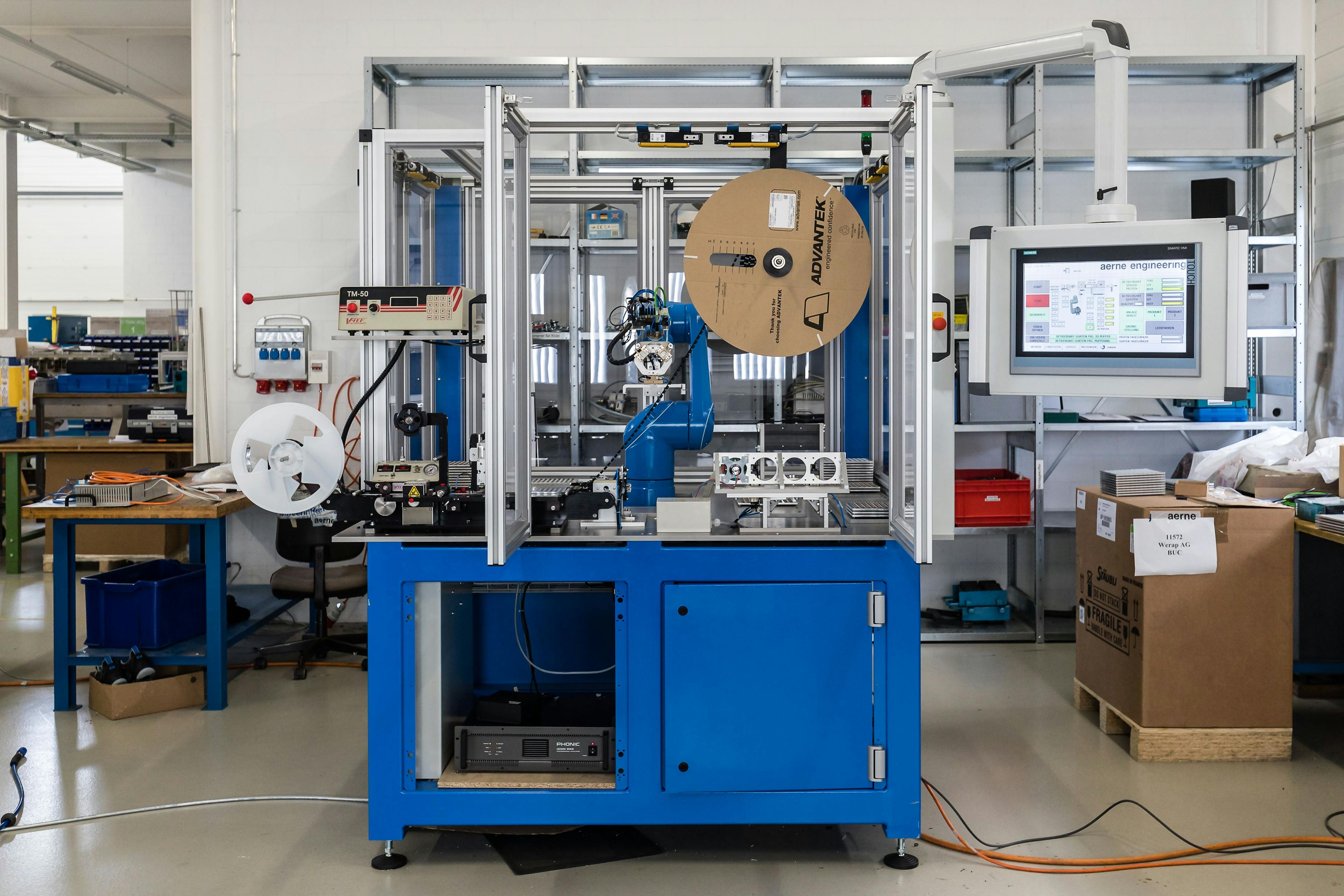

Robotic cell

The cakes pass through the robot cell and are scanned by a 3D sensor

Tracking

Cakes are tracked and the side-tilted cakes are set up.

Sheet metal gripper

Sheet metal gripper for removing the sheets from the tray trolley

Pick and Place

Pick and Place from Madeleines

Benefits

Starting point

Until now, cakes in a wide variety of shapes were sorted by hand, aligned and manually placed in a form-fill-seal machine for packaging. The cakes in particular come out of the cooler partly lying on their sides on a conveyor belt after baking. The madeleines are filled into blister packs on a second, aging machine.

Solution

We developed a packaging system for the customer for all types of cakes. This includes the automatic separation and alignment using our conveyor technology and the positioning of the cakes and filling of the Madeleines into blisters with vacuum technology and two robots. The subsequent packaging with a horizontal form-fill-seal machine is the last step of our complete system.

Advantages for the customer

- More production space due to the smaller plant

- Autonomy in the Madeleines feed was increased

- Some process steps became superfluous thanks to our system and could be completely eliminated

- Fully automatic packaging of the cakes