System film

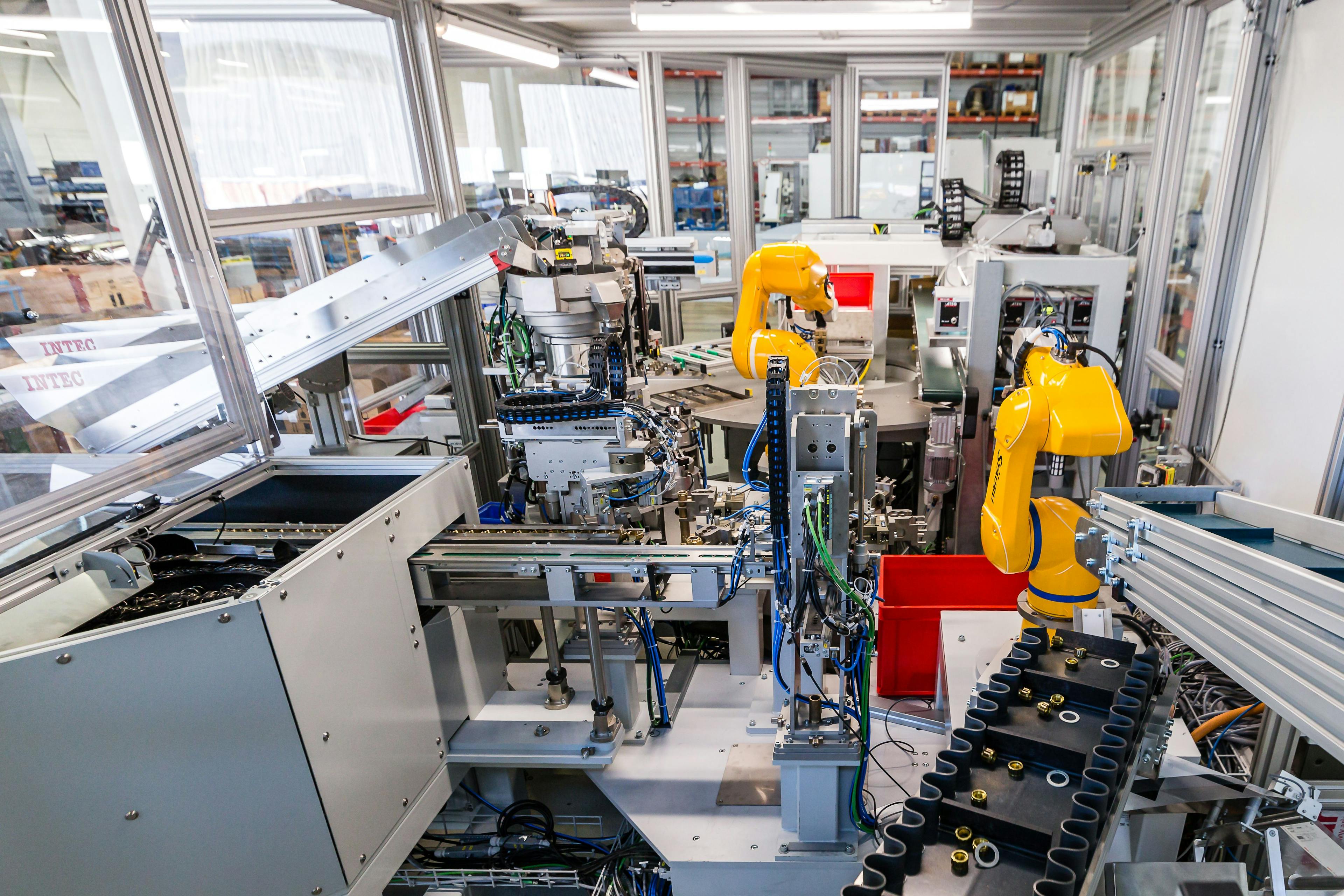

We present an automation system for pin boards.

Robot

A Stäubli robot takes the finished parts out of the tool and takes them to the vision system.

Vacuum handling unit

The topmost plate is fetched from the magazine with a vacuum handling unit.

Caulking tool

Various pins are fed to the caulking tool in 1, 2 or 5 rows. The feeder bowls were made of plastic using our 3D printer.

Benefits

Starting point

In the past, there were two manual workplaces for caulking various pins with the base plate at the customer site. Afterwards, the base plates were manually inserted in the subsequent machine.

Solution

- 3D-printed feeder bowls for feeding the pins - these are injected into the caulking tool with compressed air

- Tactile height check of all pins (quality assurance)

- 2x rotary indexing tables / 1x magazine

- Magazines can be filled in running operation

- Automatic removal of the base plates from the magazine; the lift moves the magazine into the respective position.

- Caulking tool with press cylinder

- Removal robot and vision system

- To prevent «shadowing» of the long pins, a telecentric lens was used.

Advantages for the customer

- Automated solution with 100% check

- Higher output

- Save on personnel

- Autonomy: 1 hour