Benefits

Starting point

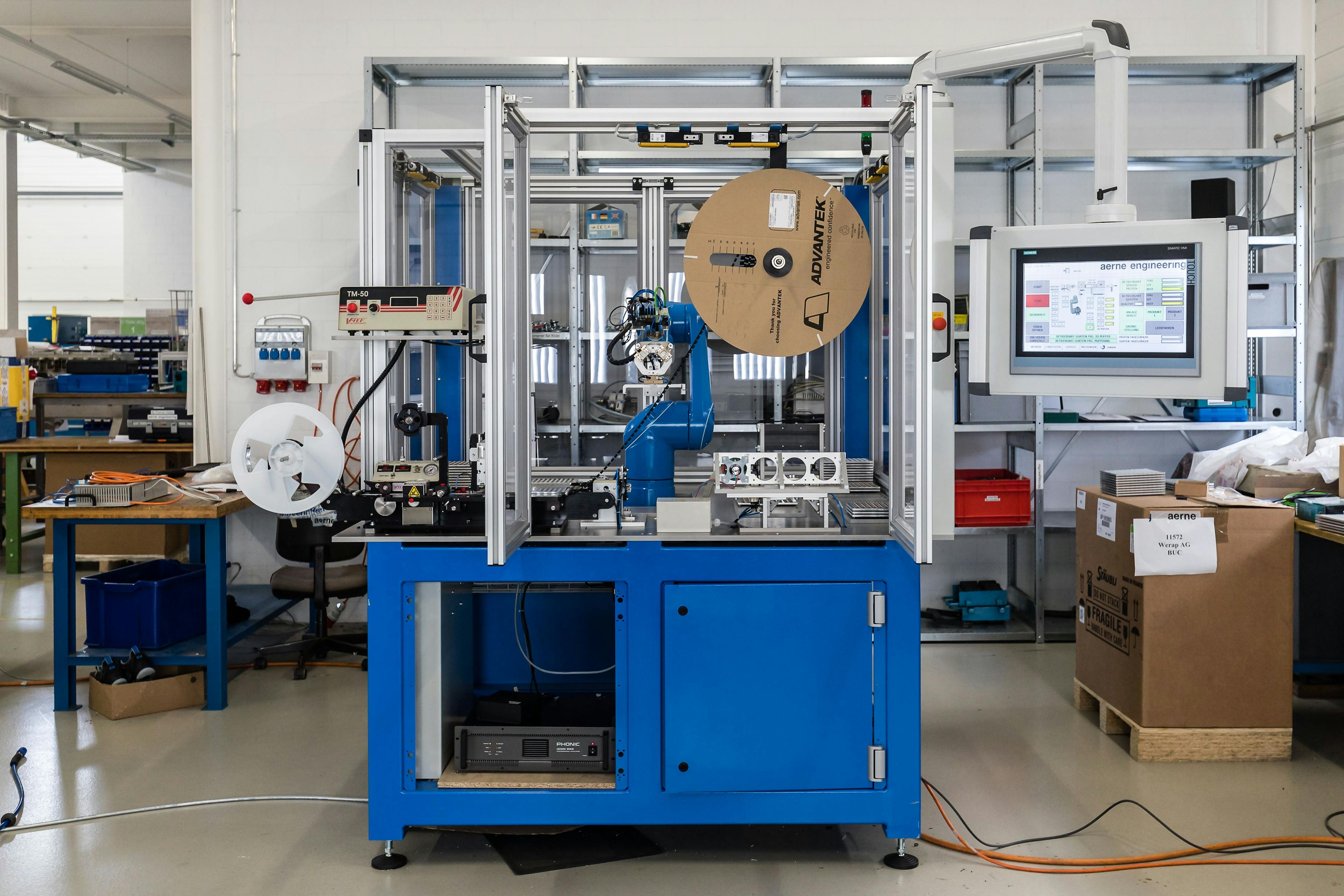

Today, our customer's switch range consists of many product variants. To ensure that all products are correctly configured and assembled, a test system for two product groups is to be developed and built.

Solution

The various switches are placed manually on two accumulating belts and are transported to the stopper. The removal gripper takes a switch and passes over a DMC reader. This allows the switch to be identified and the respective test program is loaded. In this position, a first side is tested. After this test, the switch is gripped by the robot gripper and the switch is brought into the test setup. There, the other sides are inspected by the various cameras. In OK inspection, the switch is placed on the output accumulating belt and transported out of the plant. For NOK testing, the switch is placed on the NOK belt.

Advantages for the customer

- Parts assembled by hand are 100% inspected

- Large autonomy due to feeding belts

- Features can be configured differently depending on type.

- Testing is contactless