Benefits

Starting point

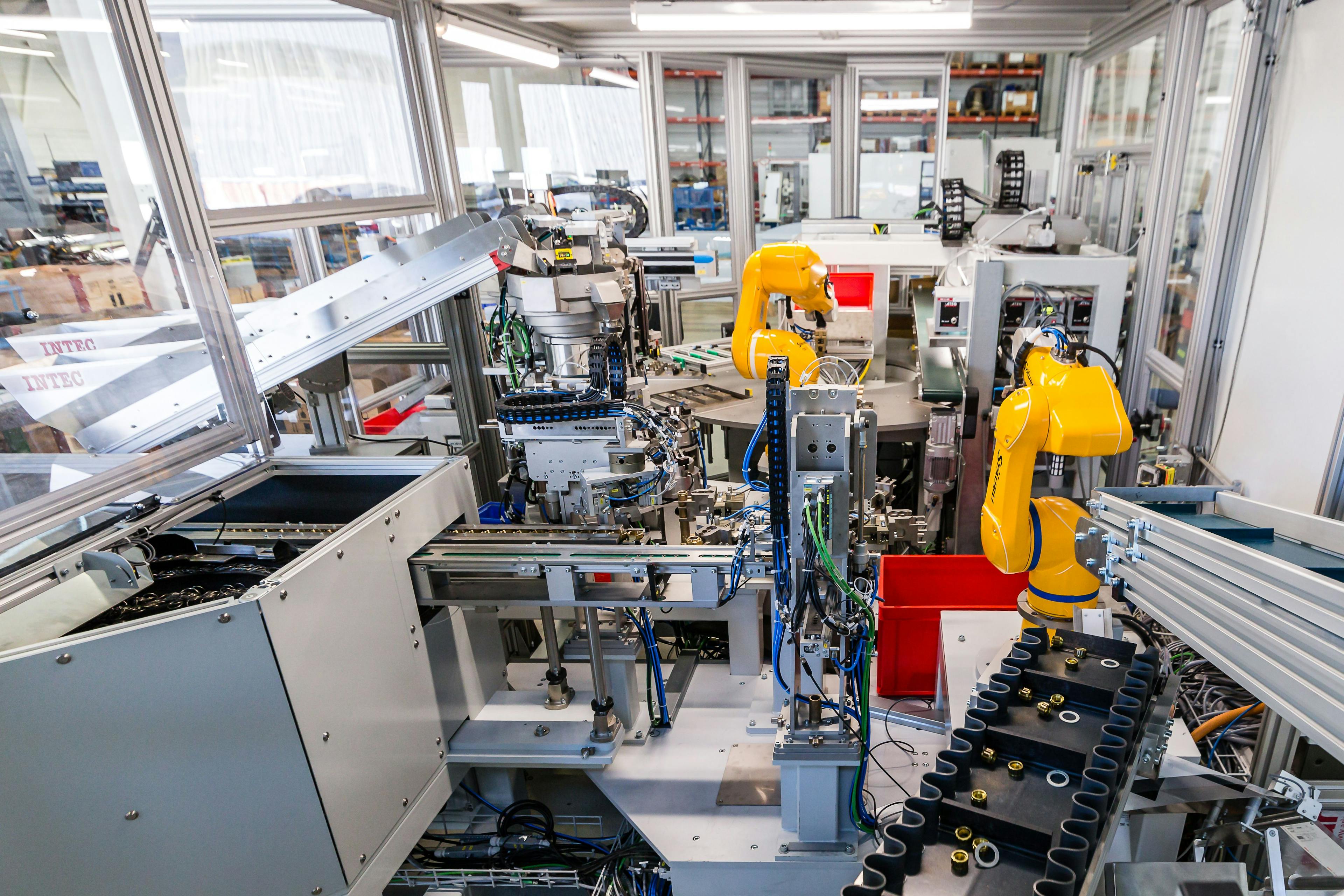

Lapptec produces cable glands, among other things. A cable gland consists of a connection piece, a seal and a terminating nut. These are available in various sizes. Lapptec wanted to produce all versions on one system.

Solution

For the various sizes, different chicanes and outlets were produced as interchangeable parts for the feeder bowls. A separate interchangeable part cabinet was provided for handling all the interchangeable parts, in which all can be cleanly placed. The connection pieces come from this lying down, its alignment detected by a camera, and this information is passed on to the next handling unit. This handling unit places the connection piece on the linear transfer system in the cavity for the corresponding connection piece. A ram presses on the fins, so that the next seal can be better placed in the connection piece. The seals are fed standing up. The seal is pressed onto the connection piece with a handling unit with an additional pressing axis. The next camera detects the depth and presence of a sealing ring. A screwdriver then screws the nut onto the connection piece. The depth is defined via a slide, which serves as a stop. Another camera detects the presence and screw-in depth of the nut. In addition, as a final check, the color of the connection piece and nut are checked for correctness. Finally, the assembled cable gland is removed via a handling unit and is deposited on the corresponding chute (OK or NOK).

Advantages for the customer

- High flexibility of various components

- Very fast cycle time

- Short retrofit from one part to another