Replacement of old system

The old image processing system, which ran on an industrial PC with Windows XP, was increasingly becoming a risk. In addition, the original supplier no longer existed. The ideal time to switch to a new and long-term, functioning smart camera solution from aerne engineering.

Smart vision

aerne engineering has replaced the two systems with two smart camera solutions (Cognex D900), which perform classification using a trained deep learning-algorithm. The new vision-system classifies the containers more precisely and reliably than the old system.

Proof of concept as a benchmark for the new system

An extensive test study prior to implementation, in which a large image set was recorded and the algorithm trained, demonstrated the effectiveness of the new system.

Anomalies classified 100 % correctly

Label residues, minimal differences in colour and geometry, missing imprints and contamination no longer impair the image processing procedure. If the containers are correctly orientated, the container type can be classified 100 % correctly.

Reliable vision inspection

Misaligned containers, containers that follow each other too closely, or contamination and foreign objects, such as cardboard boxes, are reliably sorted out.

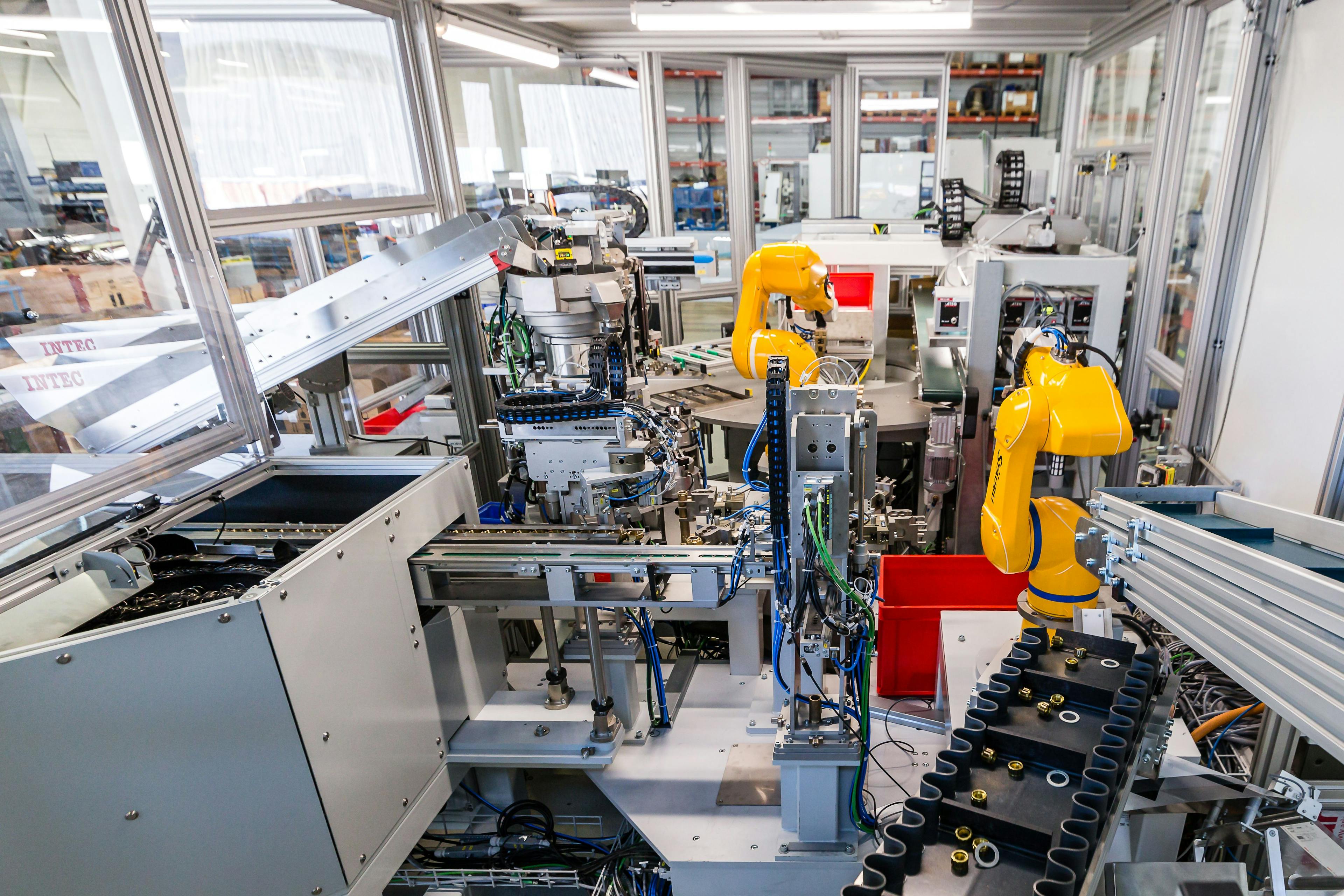

Overview and control are essential in logistics. Automated process monitoring of transport containers plays a decisive role for large-scale distributors. We were able to develop and implement a new inspection system for container sorting for COOP.