Benefits

Starting point

For these assembly and testing tasks on the expansion tank, aerne engineering may design and build a testing and assembly system. In this production line, a tank (upper and bottom parts made of plastic) is injected. Afterwards, these are welded together with a hot-gas welding system. To check and ensure the tank is leak-tight, an automatic leak test is now required. In addition, a venting screw must be inserted and a marker arrow pressed in, which marks the correct position of the lid. In order to install the finished tanks, a rubber grommet must still be pressed on.

Solution

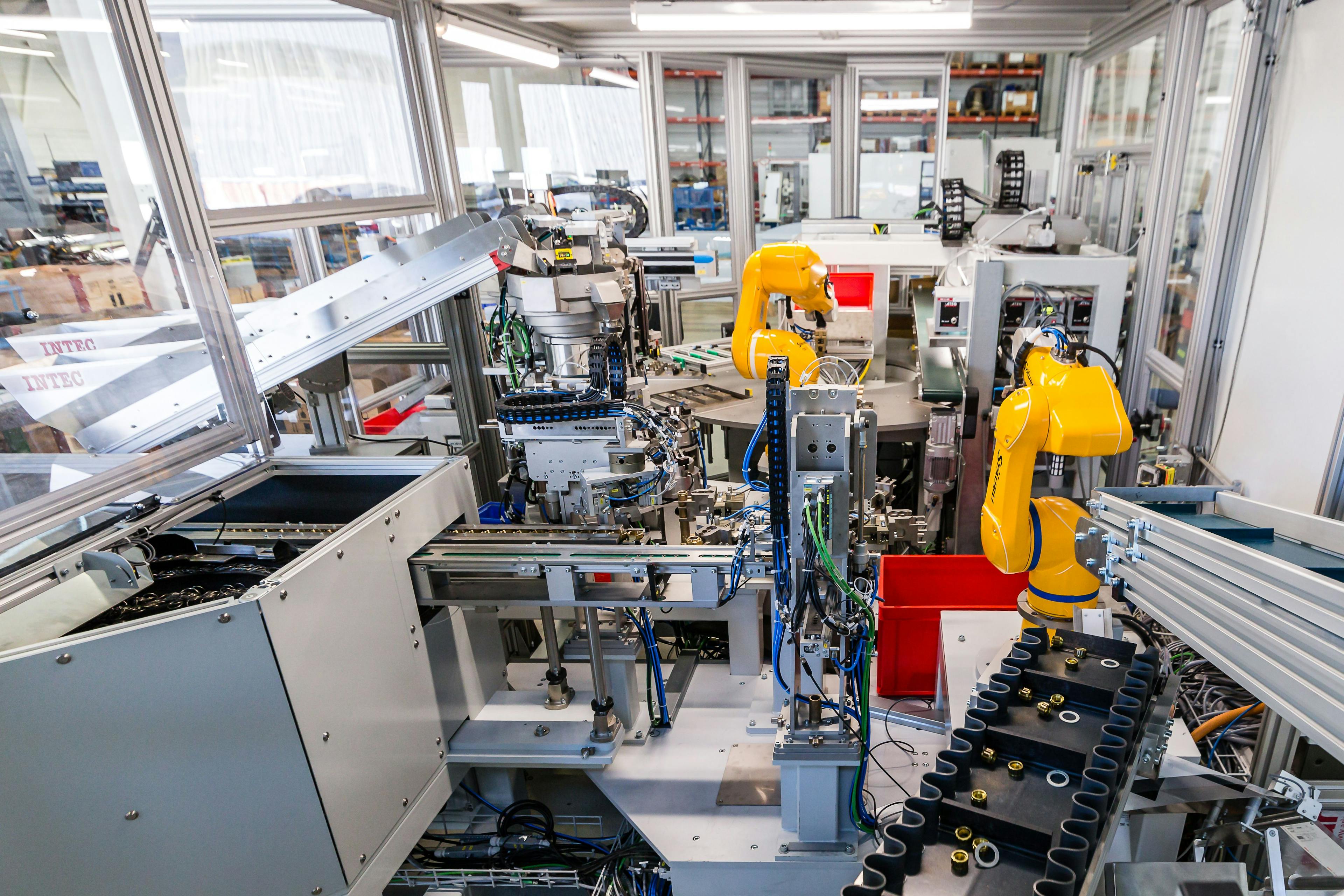

The tanks are manually inserted in the workpiece carriers in the testing system after hot-gas welding. These run through the system on a chain conveyor and are lifted and centered on the screwdriving station for the venting screw and leak tests. By means of special connections, the openings in the tank are sealed and a highly precise leak tester determines the leak-tightness of the tank. Then, the parts are removed from the transfer system by a 6-axis robot and placed in the arrow mounting unit. Here, a spiral conveyor conveys the arrows to a linear rail, whereby the correct position is checked by a Cognex camera, and, if necessary, the arrows are fed back into the spiral conveyor. A handling unit with a vacuum gripper takes the arrows out of the feeder and presses the arrow into the tank. Then the tank is inserted in the grommet mounting device with the 6-axis robot, where a cylinder likewise presses the parts into the tank from a feeder. As a last step, the tank arrives at the inspection and marking station. Here, using two cameras, the correct mounting of the arrows and grommet are checked and a needle marker embosses the date with a daily serial number into the tank. Finally, the tank is removed by the robot and is deposited on the good-part rotary plate or on one of the four separate bad part belts.

Advantages for the customer

This entire production process is accomplished in one run-through. Manual assembly tasks are omitted and the test processes can be performed with modern technology, saving time. The result is that our customer has a lower throughput time per housing and the quality of the products increased greatly.